Introduction

History of TBM technology of China

Research trend of TBM technology in China

State Key Laboratories (SKLs) in China

Unique achievements and future plans of Chinese TBM technology

Conclusions

Introduction

Along with the booming of China’s economy, the rapid urbanization in China has propped up the demand for the development of urban transport systems (Hong, 2015; Hong, 2017; Wang, 2017). Since the first subway was built in Beijing in the 1960s, a total of 32 cities in China opened rail transit operations with a mileage of 4,750 km by the end of 2017 (including maglev and tram). At present, 53 cities have set subway construction plans with a planned mileage of 9,000 km. It is expected that 6,000 km of operating mileage will be achieved by 2020. In addition, to ensure the sustainable development of urban cities, the Chinese Government has actively promoted the construction of utility tunnels. A total of 69 cities in China are building utility tunnels with the total length of 1,000 km, and the construction cost is estimated to be 88 billion (RMB) (Yang and Peng, 2016).

TBM is usually categorized into shield TBM and open (or gripper) TBM. Shield TBMs have been mainly used for soft soils and composite formations, where the applications are mostly subways and cross-river tunnels. Open (or gripper) TBMs are mainly used for mountain tunnels and diversion tunnels in hard rock formations. This paper will mainly focus on the development of shield TBM manufacturing technology in China.

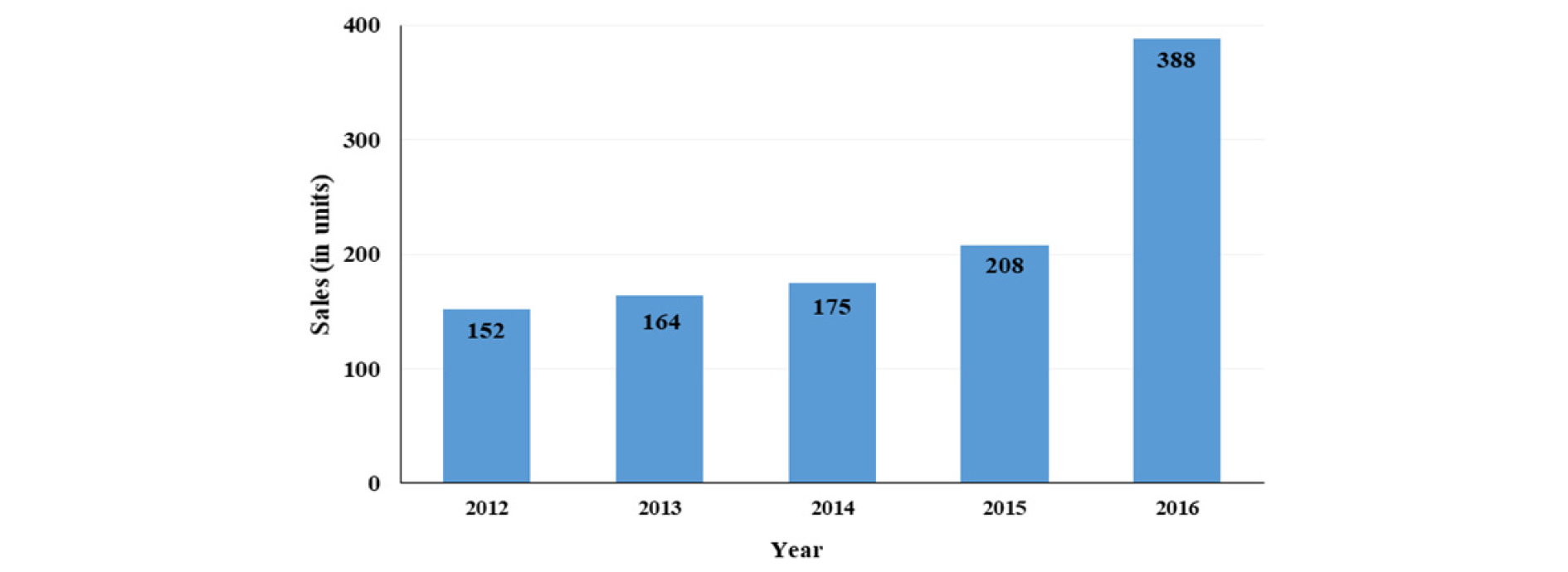

In the context of huge domestic transportation construction markets, the demand for TBM manufacturing is high and thus, the Chinese TBM industry is growing at a high rate. According to the statistics from the China Construction Machinery Association (CCMA), the total sales of TBM (in number of units) in 2016 increased by 46% year-by-year (Fig. 1). In 2017, China has become the largest manufacturer and the largest market of shield TBM in the world (CCMA, 2018). The Chinese shield TBM market will grow to a scale of approximately 7 billion (RMB) by 2020 (Hong et al., 2013).

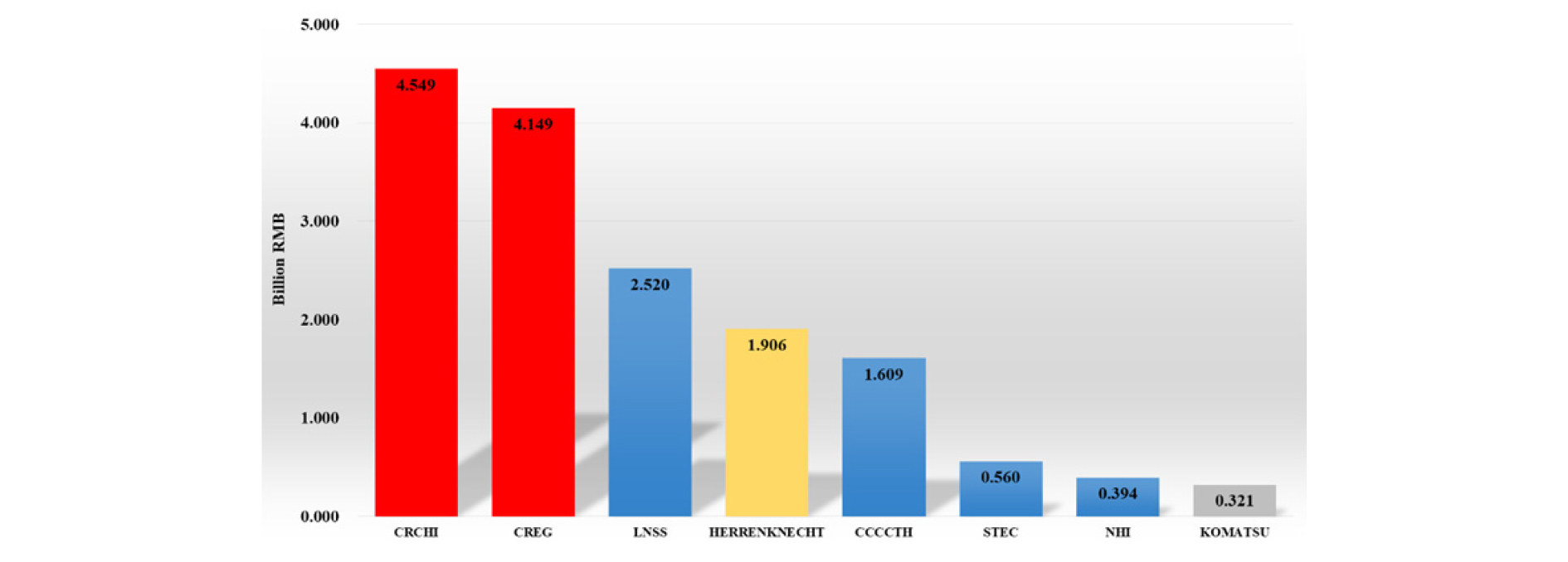

Recently, Chinese TBMs have become popularized and have rapidly occupied the domestic market while gradually entering the global market. The TBM industry of China has successfully transformed from "assembled in China" into "made in China" (Chen et al., 2016). The remarkable progress of Chinese TBM technology is based on independent innovation. A number of competitive Chinese TBM manufacturers have emerged including the six-largest TBM manufacturers: China Railway Engineering Equipment Group (CREG), China Railway Construction Heavy Industry (CRCHI), Shanghai Tunnel Engineering Co. (STEC), Liaoning Censcience Industry (LNSS), Northern Heavy Industries Group (NHI), and China Communications Construction Company TianHe Mechanical Equipment Manufacturing Co. (CCCCTH). They have captured more than 80% of the Chinese market share. The sales of major TBM manufacturers in 2016 is shown in Fig. 2.

History of TBM technology of China

The development of TBM manufacturing technology of China has gone through three stages (Chen and Zhou, 2017), namely, “early stage (1953-2002)”, “technology innovation stage (2003-2008)” and “rapid development stage (2009 to date)”.

In the “early stage (1953-2002)”, the development of TBM technology mainly focused on several subway construction projects in big cities including Beijing, Shanghai and Guangzhou. STEC played an important leading role in the development of Chinese TBM technology in this period. The hand shield TBM, blade shield TBM, Earth Pressure Balance (EPB) shield TBM were developed in this period.

In the “technical innovation stage (2003-2008)”, with the support from the “863 Program (National High-tech R&D Program)”, some key research projects were funded by the Ministry of Science and Technology of China (Table 1). Furthermore, through the introduction of advanced technology from abroad, China has developed TBMs with fully independent intellectual property rights narrowing the gap between Chinese and international levels Chinese TBM manufacturers developed their own technologies for the design of different types of TBM.

Table 1. TBM related research topics supported by the ‘‘863 Program’’ (from Ministry of Science and Technology of China homepage)

Based on the huge domestic shield TBM market, TBM technology of China entered the “rapid development stage” since 2009. Many research projects on TBM manufacturing and tunneling technologies were supported by the “973 Program (National Basic Research Program)” as listed in Table 2.

Table 2. Shield TBM related research topics supported by the ‘‘973 Program’’ (from Ministry of Science and Technology of China homepage)

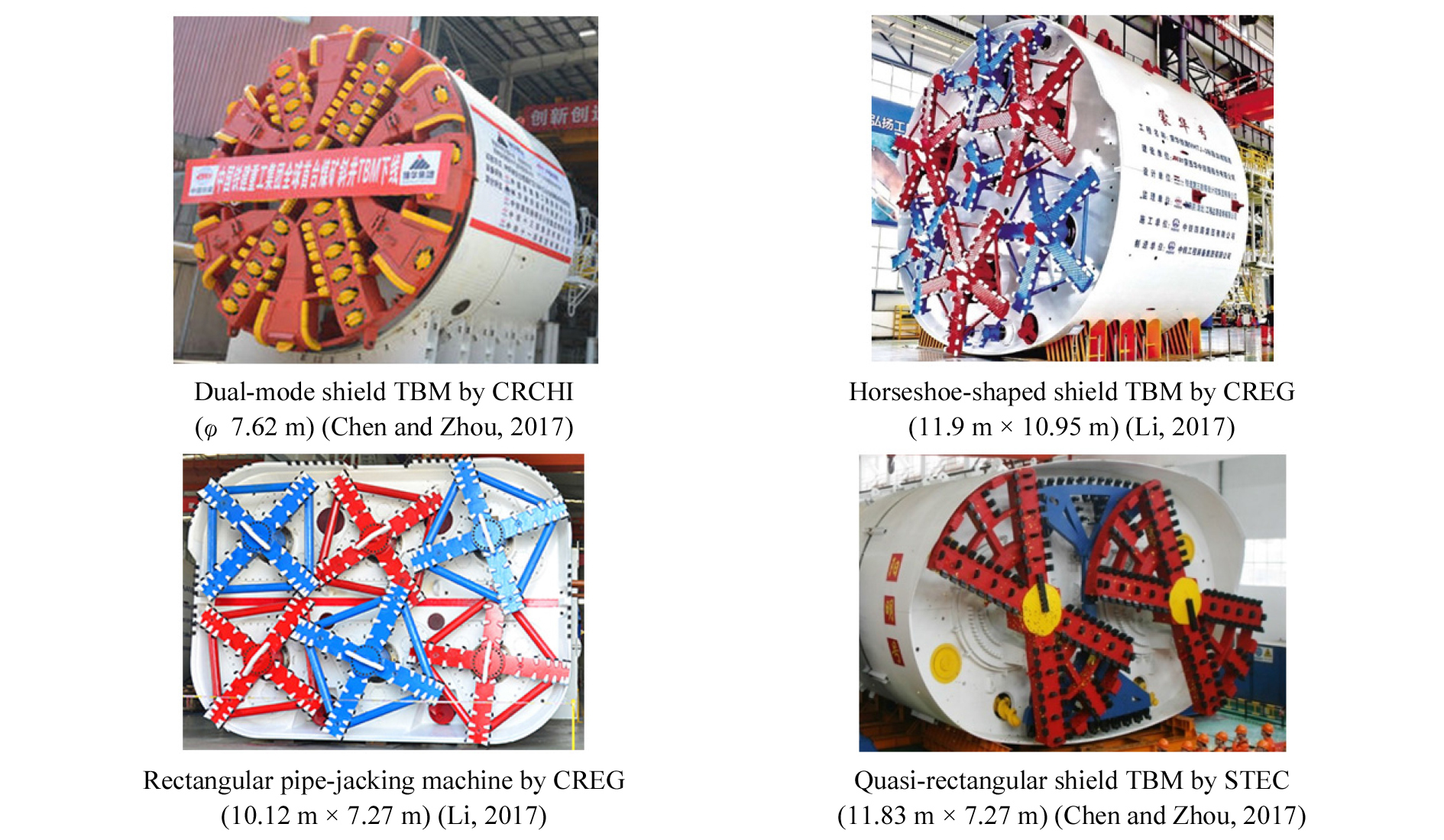

For decades of effort and development, major breakthroughs and achievements were successfully made in the development of key core technologies in shield TBM manufacturing and mechanized tunneling. Some notable shield TBMs made by Chinese manufacturers are listed in Table 3 and shown in Fig. 3.

Table 3. List of some notable shield TBMs made by Chinese manufacturers

Research trend of TBM technology in China

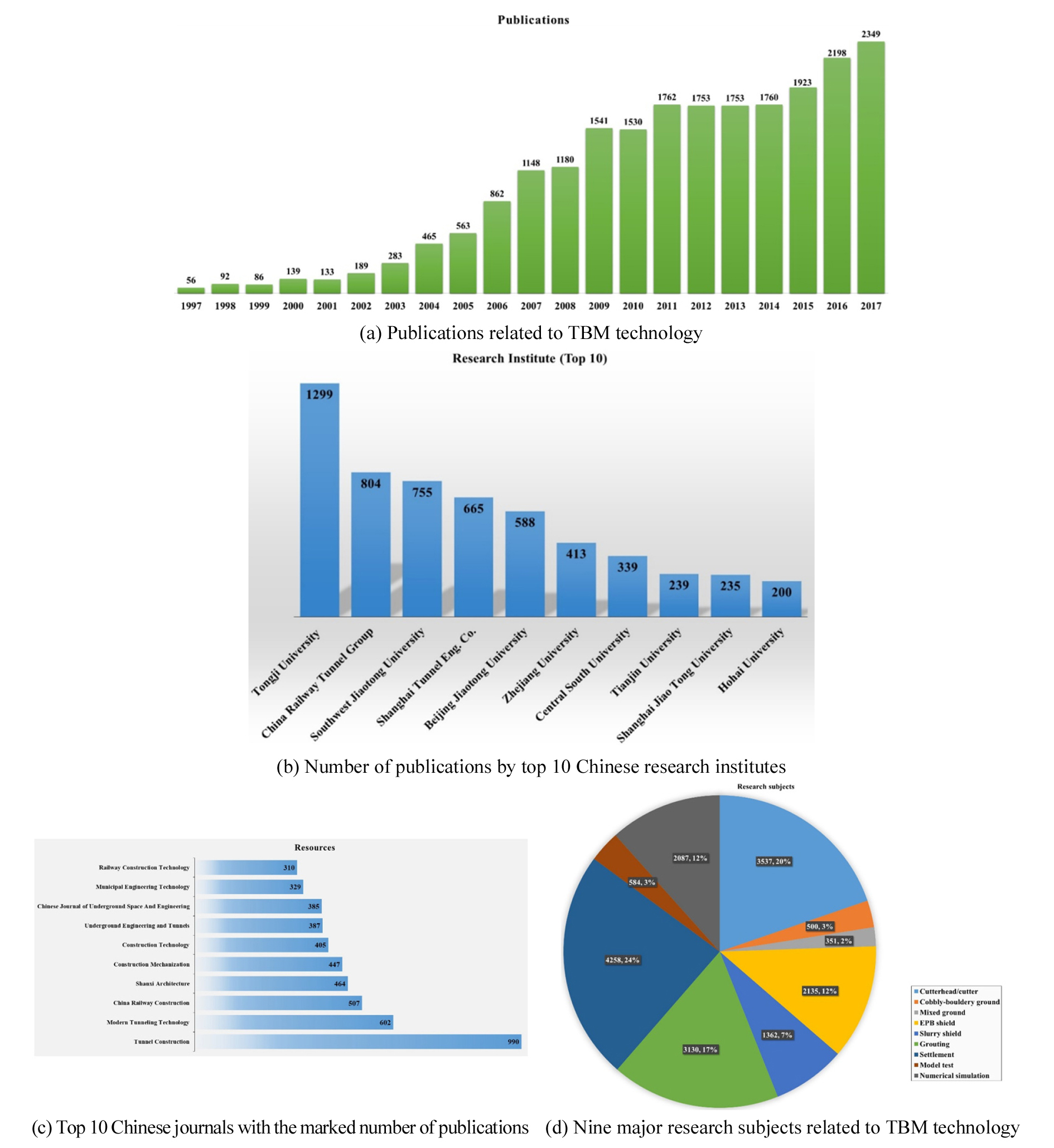

In recent years, research on TBM technology has become very popular in China. The number of publications related to TBM technology during the past two decades is presented in Fig. 4(a). Based on the statistics from the China National Knowledge Infrastructure (CNKI), it can be found that Tongji University, China Railway Tunnel Group, and Southwest Jiaotong University are the most active research institutes in China (Fig. 4(b)). TBM related journals are listed in Fig. 4(c) and “Tunnel Construction” which is the most widely renowned journal in China. The research subjects in TBM technology are shown in Fig. 4(d), where settlement, cutter, grouting techniques are research hotspots. Although these publications are mostly published in Chinese which are difficult to access for Korean academics and industries, they are still worth referring to for our future research in TBM tunneling field.

With the increasing and wide application of TBMs, the TBM tunneling techniques have greatly evolved in China (Wang, 2014). The relevant content of TBM tunneling techniques will not be covered in this paper. However, some typical cases where key techniques of TBM tunneling in difficult (or complex) ground conditions can be found such as for mixed ground (Liao, 2012; Wang, et al., 2016), cobbly-bouldery ground (Yang et al., 2011; Le et al., 2012; Sun et al., 2017), super long tunnel with large diameter TBM (Deng, 2016; Wang, 2017), high geo-stress region (Fang et al., 2013; Song and Zhao, 2017), and underwater tunnel with high water pressure (Xiao, 2018; Zhu et al., 2018).

State Key Laboratories (SKLs) in China

To solve the technical challenges and ensure efficient TBM tunneling in complex geological conditions, China has increased the investment for TBM manufacturing and tunneling technology. Some specialized and professional research institutes have been established to carry out relevant research projects of TBM technology funded by the government.

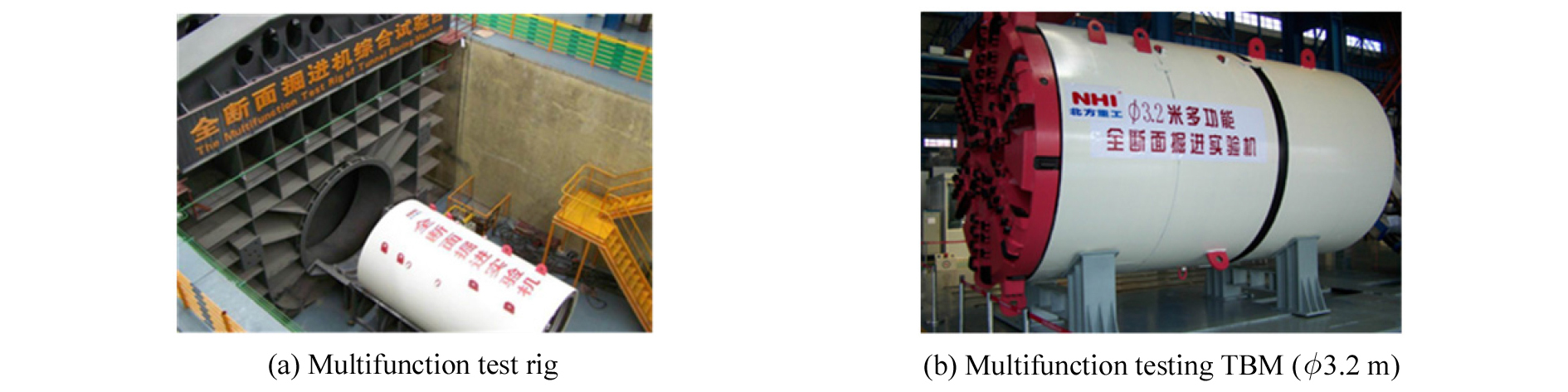

Two state key laboratories have been established for the development of TBM technologies. The 'State Key Laboratory (SKL) of Full-Face Rock TBM' which belongs to NHI was founded in 2004. This laboratory has a series of advanced test facilities including a multifunction test system of TBM (Fig. 5).

The 'SKL of Shield TBM and Boring Technology' operated by CREG was set up in 2010. Since then, the laboratory has won a total of 35 scientific and technological achievements, including the first prize of State Science and Technology Progress Award in 2012. Some experimental facilities of the laboratory are shown in Fig. 6. Currently, three main research topics have been set:

(1) Cutterhead and cutting tool technologies: to make the design of cutterhead and cutting tools to accommodate different geological conditions; to study the key technologies of cutter geological adaptation; to establish the theory of high-efficient rock breaking for cutterhead and cutters; and to develop industry standard for cutting tool design and manufacturing.

(2) Control technology of shield TBM tunneling: to establish the information management system of shield TBM tunneling which can provide technical advice and technical service for tunneling projects.

(3) System integration technology: to develop the machine integration and control technology; and to develop remote automatic diagnosis system and intelligent decision system.

Unique achievements and future plans of Chinese TBM technology

Through the consistent effort from the Chinese TBM industry and academia, many unique advanced technologies have been developed including (1) New driving technology (such as permanent magnet synchronized driving technology and electro-hydraulic driving technology), (2) cutterhead and cutter repair technology (such as replacement of cutter tools under atmospheric pressure and robot-assisted detection and repair technology), (3) rapid muck removal technology (such as high-efficiency crushing technology of large boulders), and (4) adaptive technology for non-circular sections (Zhao and Chen, 2013; Chen et al., 2016; Wu et al., 2016; Chen and Zhou, 2017; Li, 2017).

The main development trends in the future are as follows:

1. Chinese TBM manufacturers are developing miniature TBMs for a build-up type shield TBM (several miniature TBMs to be assembled together). CREG has already applied a prototype machine to the construction of an underground parking lot.

2. TBMs for great depth with high geo-stress, high water pressure, and for large-diameter tunnels are under development to accommodate diverse demand for efficient tunnelling.

The adaptability of TBMs in the complex and difficult geological conditions, robustness of TBMs, and reliable cutter life would be even more demanding in the future (Wang, 2014; Liu et al., 2015). The long-term vision of Chinese TBM technology is to realize more efficient and automatic design, modular manufacturing, remote and intelligent monitoring, controlling and maintenance of TBMs.

Conclusions

China is the country that has the most tunneling projects in the world at present. Based on the diverse projects, the TBM manufacturing industry of China has rapidly grown in the past decades. Narrowing down the technological gap with advanced countries, the Chinese TBM industry still has tasks in enhancing the reliability of TBMs, independent technological innovation, and development of more intelligent design and manufacturing methodologies.

From the Chinese history of TBM technology development, some implications and beneficial enlightenment can be attained. TBM industry is technology- and capital-intensive. It requires huge initial capital investment and many engineering projects to apply its technologies. The Belt and Road Initiative (BRI) and strong governmental support made the Chinese TBM industry viable. Manufacturers have been working together with research institutes and universities in many projects. It is worth noting that the technical development could not be made without diverse tunneling projects, feedbacks from job sites, and modifications of the technologies.

TBM industry of Korea is small in size due to the limited number of national tunneling projects and the preference of cost-effective drill-and-blast tunneling over TBM tunneling in many cases. On the contrary, the Korean government has supported R&D projects for the development of core technologies in TBM design, subsea and utility tunnels by TBMs. In case that the government and the potential manufacturers are interested in TBMs, the Chinese history of TBM technology development will make an excellent case to refer to.